THE FLEXIBLE MANUFACTURING WORKSHOP

Project Leader: Simon d'Hénin

Assistant Designer: Justyna Swat

Project Coordinator: Margot Casimir

The ENSCI FabFlex offers a space to reflect on the economic, social, technological, scientific and industrial aspects of the revolution in flexible - digital - manufacturing: CNC machines, 3D printers, dedicated design software, etc.

These manufacturing methods question the new ‘Design, Produce, Distribute’ manufacturing models: customised manufacture, neo-artisanal production, local on-demand industrial manufacturing. This space extends the story of rapid prototyping, CAD/CAM, non-standard architecture, etc. It furthers the discussions that took place at the Bauhaus around the issues of production conditions in heavy industry and in craft-based environments. It is therefore a space for invention as well as production. Social innovation is also addressed, and is an important aim of this workshop.

FabFlex is a manufacturing laboratory that offers each student the opportunity to consider the practice of industrial design in a context where he or she is directly involved in the production chain. More specifically, the aim of FabFlex is to put manufacturing at the heart of the creative process, so that it becomes an integral part of the creative project processes, rather than simply the final stage of material realisation. At the point where design meets production, it create a space in which students can experiment with new processes for object creation.

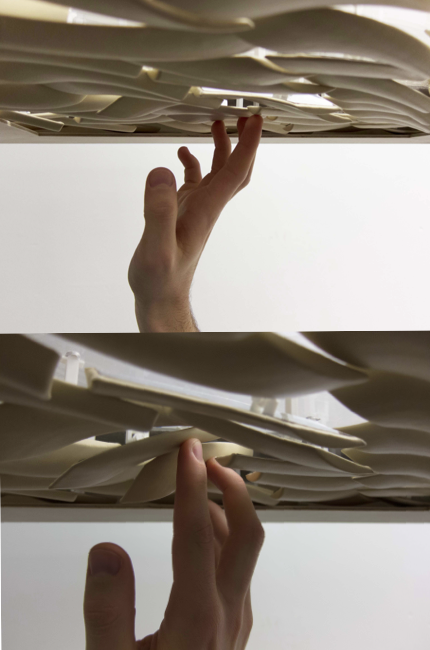

So what types of object are made possible in the context of FabFlex? Which methods and processes can be used to achieve them? In contrast to the mechanical (re)production processes used in industry, such as moulding and stamping, which mass-produce a single type of object, manufacturing processes like 3D printing and digital milling make it possible to consider producing variations within production runs or even one-off manufacture by updating the digital model. So what types of object can we envision on the basis of using new processes that hold out the possibility of creating a multitude of 3D models and manufacture each one by means of 3D printing? What kind of modular and shared forms of design can also be envisioned in this context? What types of manufacturing sequence/combination can be envisaged by using all the many tools available? What materialities, finishes and perception does the resulting object have?

The goal of this workshop is to explore the most relevant types of object for production in the FabLab environment, and in the broader context of Flexible Manufacturing, and then to propose the most meaningful objects for this design/produce/distribute methodology. The resulting proposals are assessed on the basis of the compatibility of the object with its manufacturing system.

Doing, experimenting and cross-disciplinary working are central to the project, which is less about sticking with hypotheses, and much more about developing the design/production chain, making it work and - if possible - progressing to the production of finished objects and distributing and sharing their ‘recipe’. Students must therefore use the machines provided by the design school (3D printer, digital milling machine and the machines in the wood, metal, plastic, modelling workshops, and the digital studio workshop) not as modelling or prototyping tools, but as production tools. Some projects are manufactured by our external partners.

TOPICS COVERED

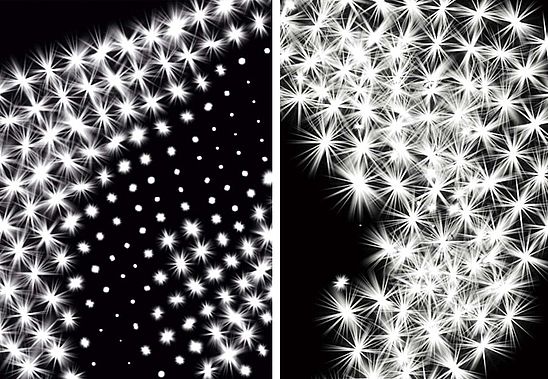

FabFlex / Sensitive Glass; Energy & Robotics; Car Interior Lighting; Free from...; Physical interactions; Digital aesthetics

HALO

PROJET D'ATELIER DE FANNY GIAMPICCOLO

—See